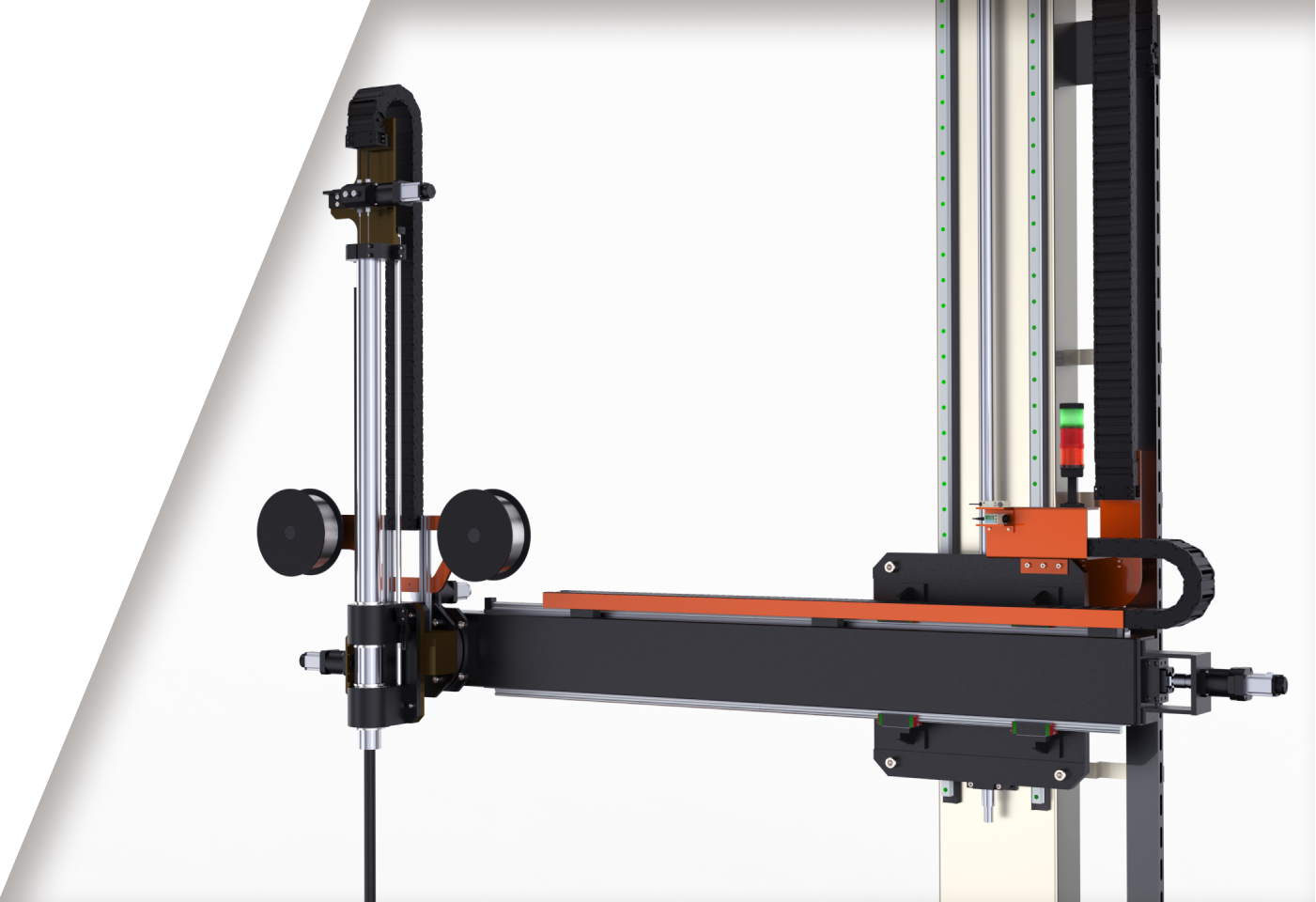

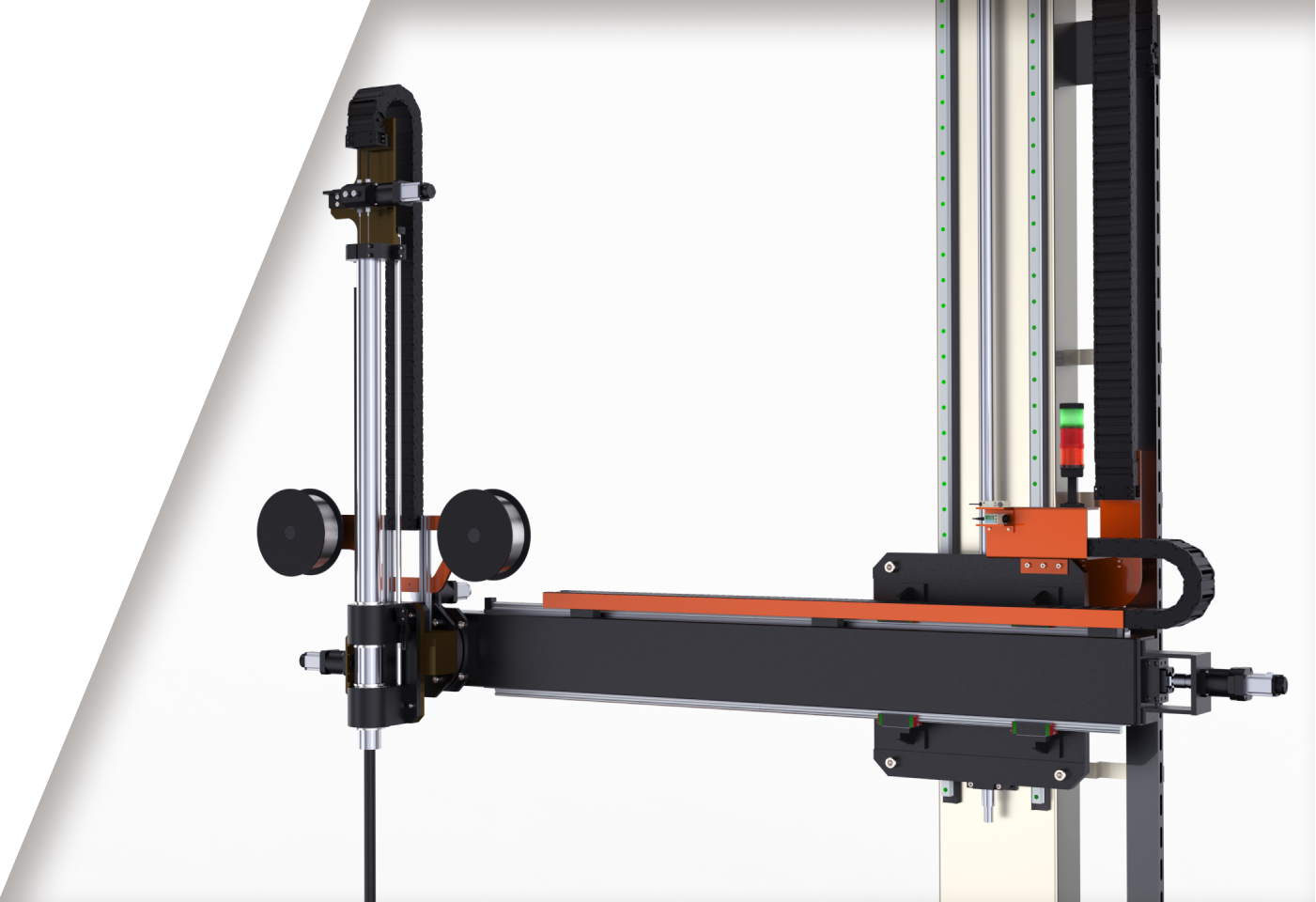

Xl - Vertical Cladding

station

A large column & boom system ideal for cladding of large elbows & flanges.

KNOW MORE

A large column & boom system ideal for cladding of large elbows & flanges.

KNOW MORE

The system incorporates a column & boom manipulator with floor turntable. The column & boom are made out of light weight heavy duty aluminium extrusion. (option of a 2nd turntable or welding positioner to maximise productivity).

Xl - vertical cladding system is designed & engineered as a heavy duty column and boom welding manipulator, fitted with servo motor controlled precision slides, wire feeder and welding torch.

The xl-vcs standard configuration is equipped with a turntable of 2.5mtrs. The system can be fully customised to the requirements of the end user.

Weld overlay of flanges up to 58” and elbows up to 46”

In house design & manufacturing of column & boom with options ranging from steel structure to extrusion profiles as optional moc.

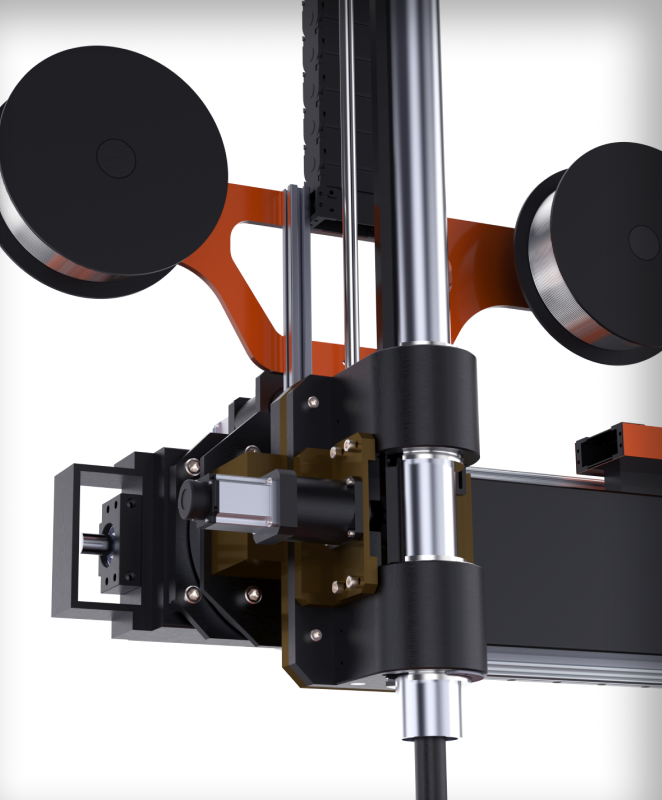

Multiple water cooled hot wire torch configurations and lengths with fixed angle or adjustable angle heads.

15” HMI with handheld wireless pendant.

Optional attachment of weld monitoring camera.

Column & boom series range from 2m x 2m to 6m x 3m

A versatile and cost-effective solution for larger size components.

Heavy duty precision slides driven by servo motor

Provision for 200kg jumbo spools / wire drums.

Remote diagnostics.

Data logging features.

Ewm power source with hot wire

Reduced column height vide telescopic z slides.

Perfect design for extra-large/heavy components