Our expertise is

in

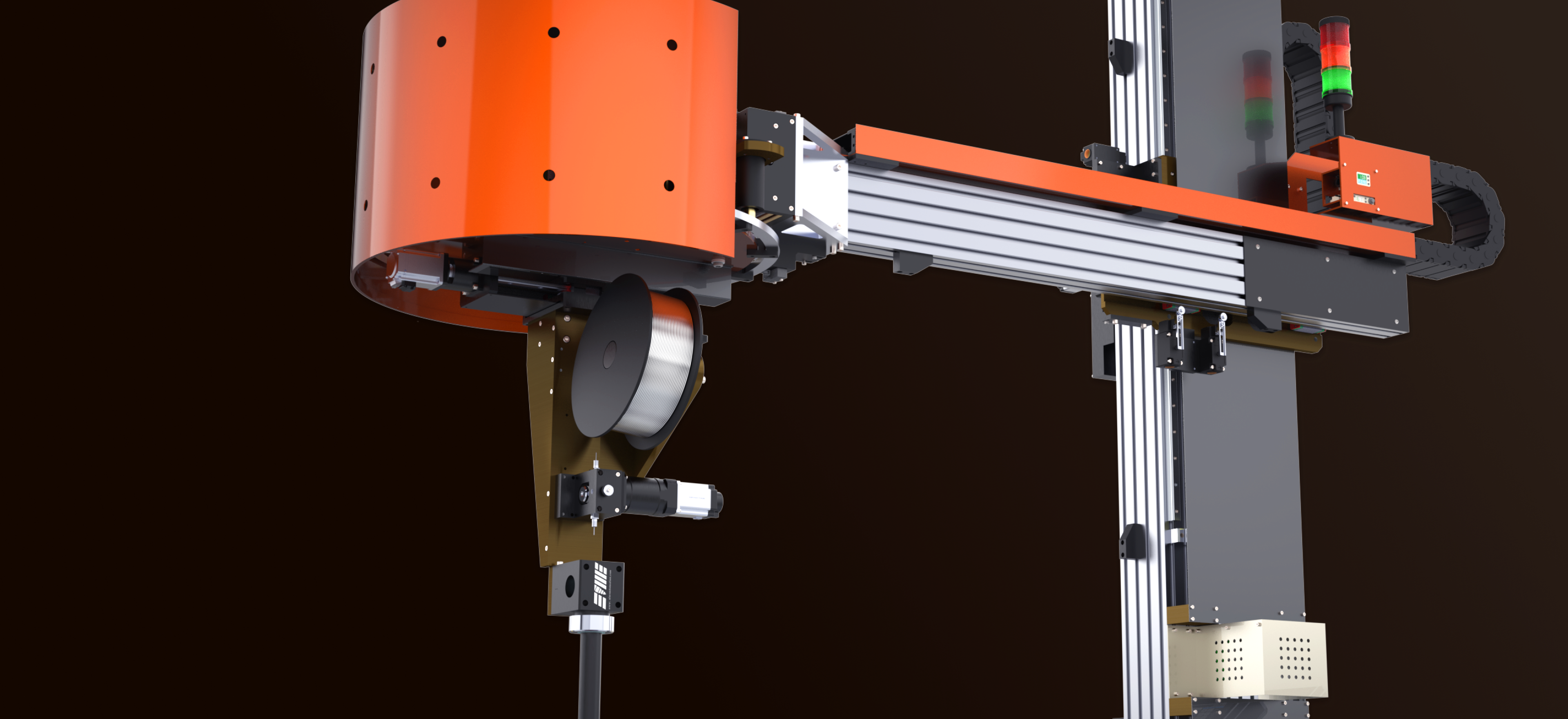

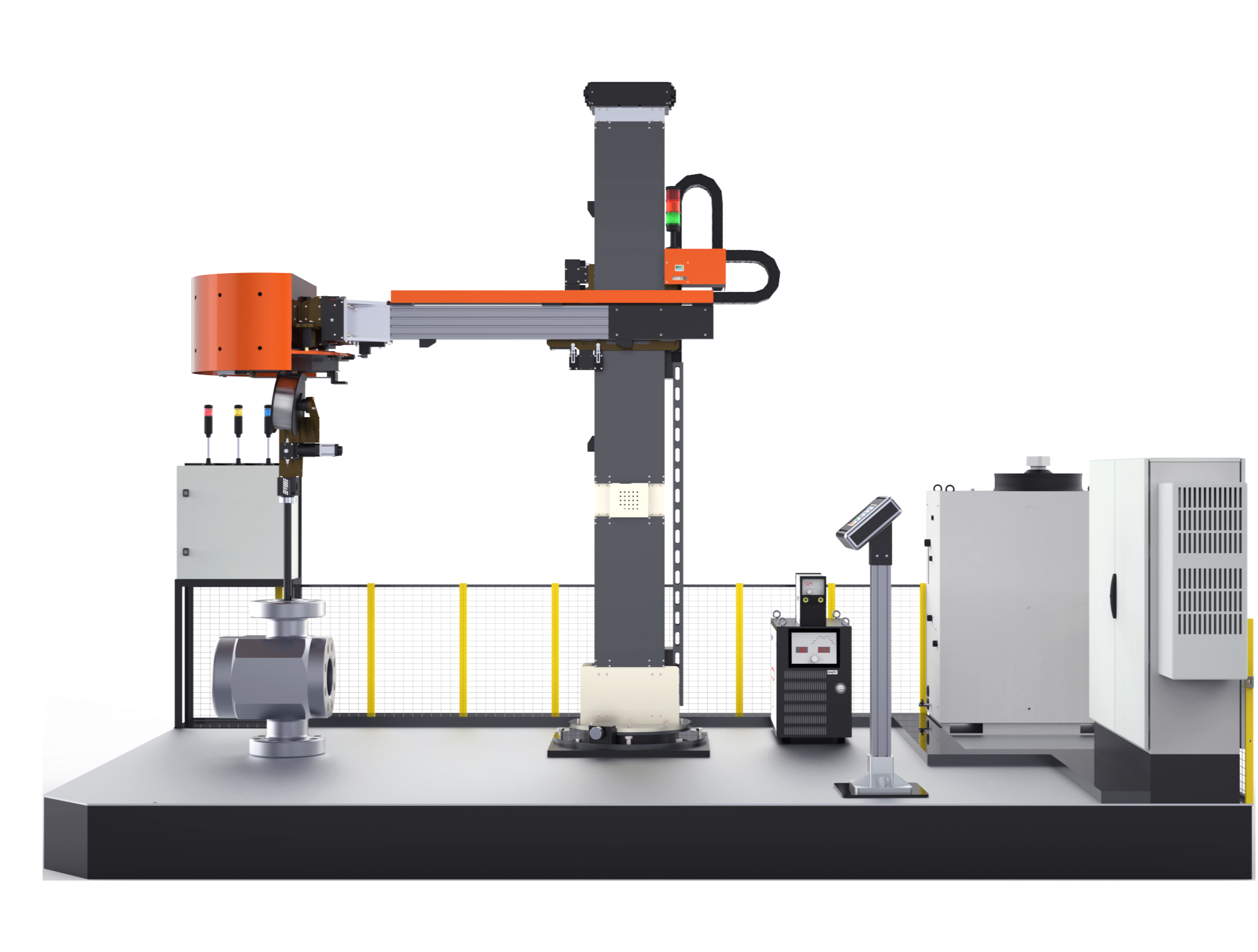

weld overlay cladding systems

Sine automation was founded with the aim of providing welding automation technologies in India and overseas. We have provided a diverse range of welding automation solutions for our clients, both in India and overseas.

KNOW MORE

Company

Environment

Goal

Innovation

Research & development

is at the core of our

organisation.

Research and development is an integral part of sine group’s approach to industrial solutions, and we have consistently invested in this area since our inception. Our continuous development has aided the identification of new opportunities and given birth to numerous innovative solutions, always with customer satisfaction as our main focus.

KNOW MORE

WHAT IS

WELD OVERLAY CLADDING?

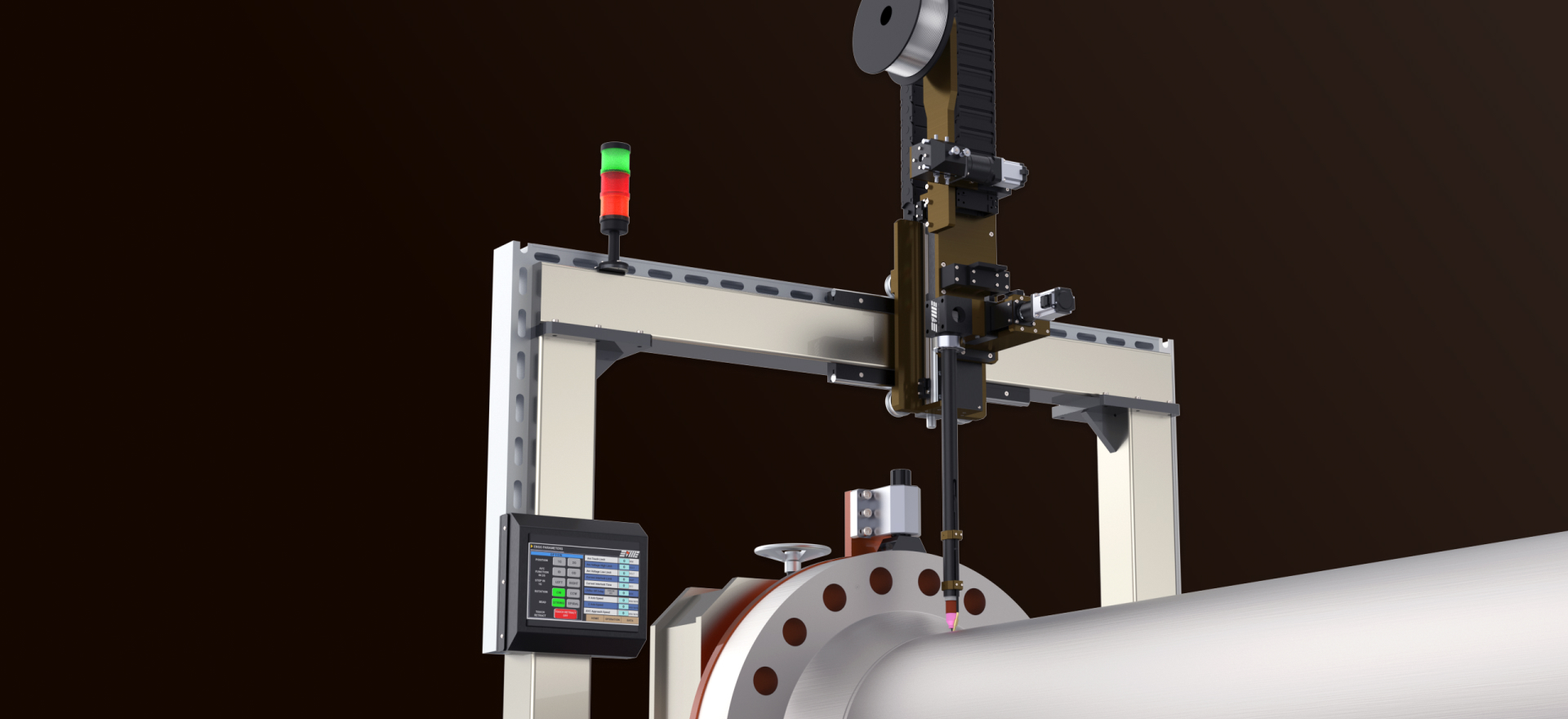

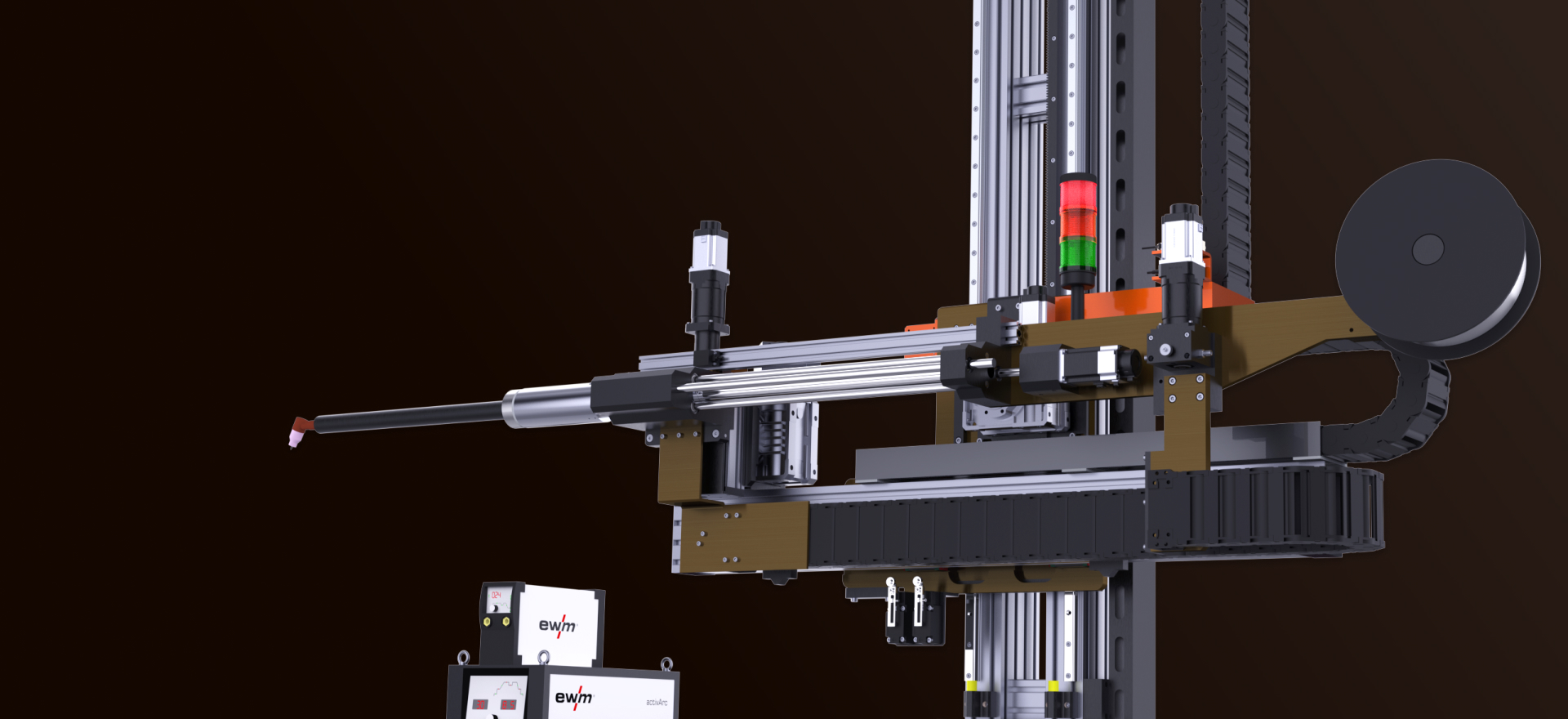

A weld overlay is a type of cladding that uses a welding process to melt a material onto the surface of another, different material, forming a base material that is resistant to corrosion and wear. The highly versatile process may require multiple passes to properly mix and bond the metals, while meeting the design and material requirements of the cladding layer.

Customers commonly use weld overlay to balance corrosion resistant properties and costs, often coating an inexpensive metal, like carbon steel, with a more expensive base layer, such as stainless steel. Our weld overlay systems are engineered and manufactured to offer solutions for a wide range of applications, including flanges, fittings, pipes, valves, pressure vessel nozzles and tube sheets for heat exchangers.

The weld overlay/ weld cladding technique is generally used for corrosion resistant applications covering oil and gas industry, chemical processing, offshore and marine industry, power plant, paper and pulp industry, as well as food processing industry, etc. Typical components that are weld overlayed include heat exchanger tube sheet, paper digesters, urea reactors, nuclear reactors, hydrocrackers, valve seats, and rf or RTJ flanges.

KNOW MORE