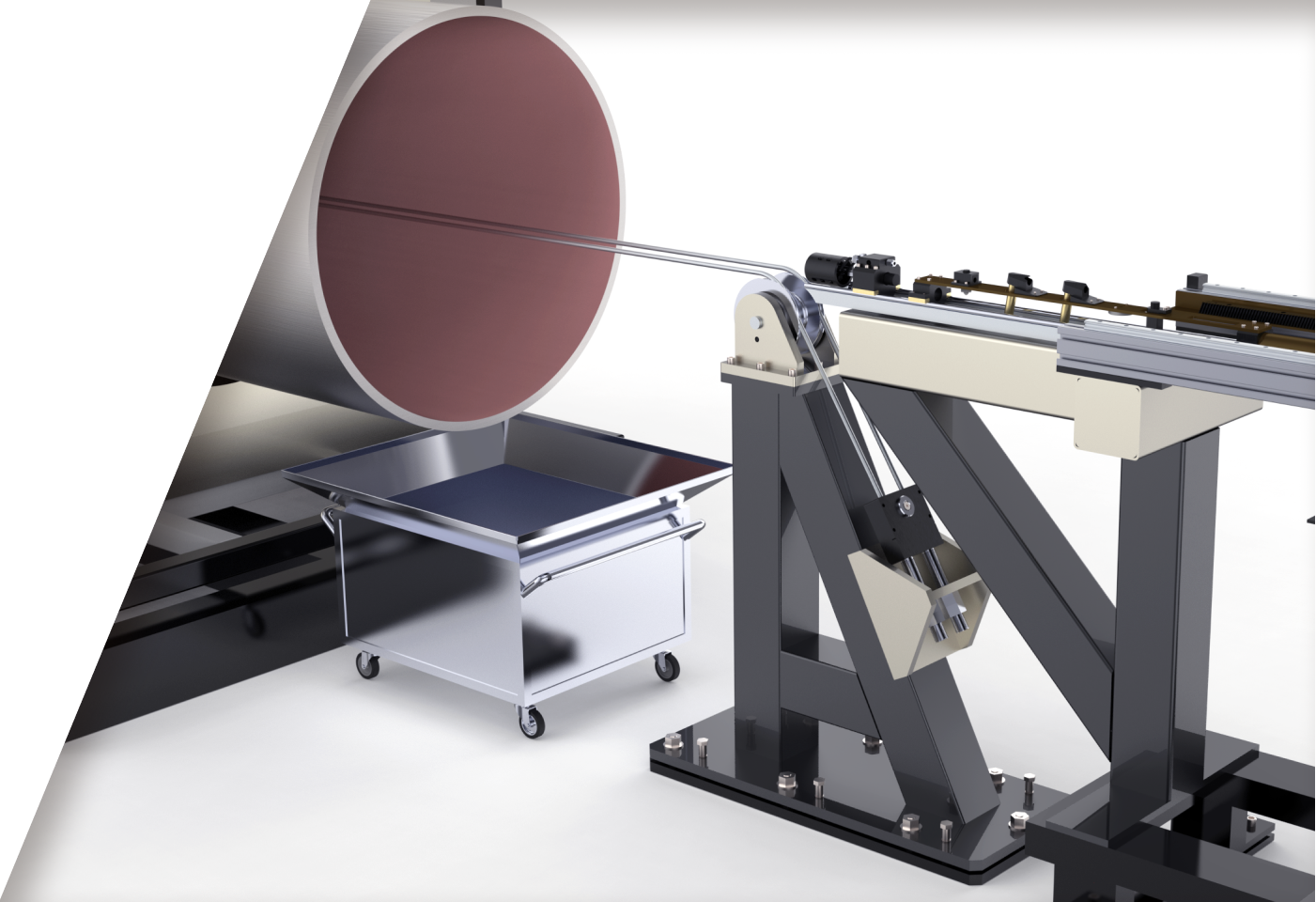

Automatic DP Test

machine

Perfect solution for automated dye penetrant test of large pipes.

KNOW MORE

Perfect solution for automated dye penetrant test of large pipes.

KNOW MORE

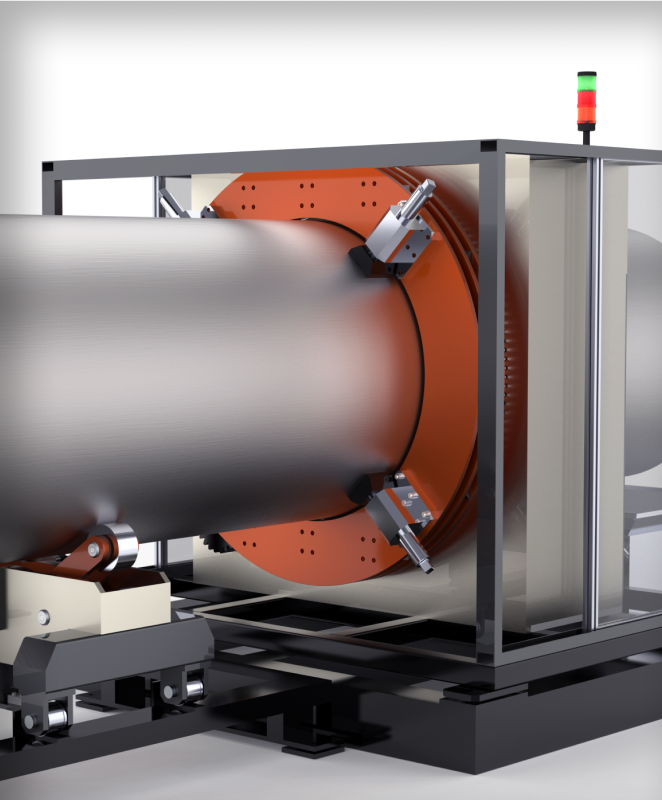

Dye penetration test machine is plc based automated system designed to ensure high quality & reliability in weld overlay products. It is used to detect welding surface defects such as hairline cracks, surface porosity, and fatigue cracks.

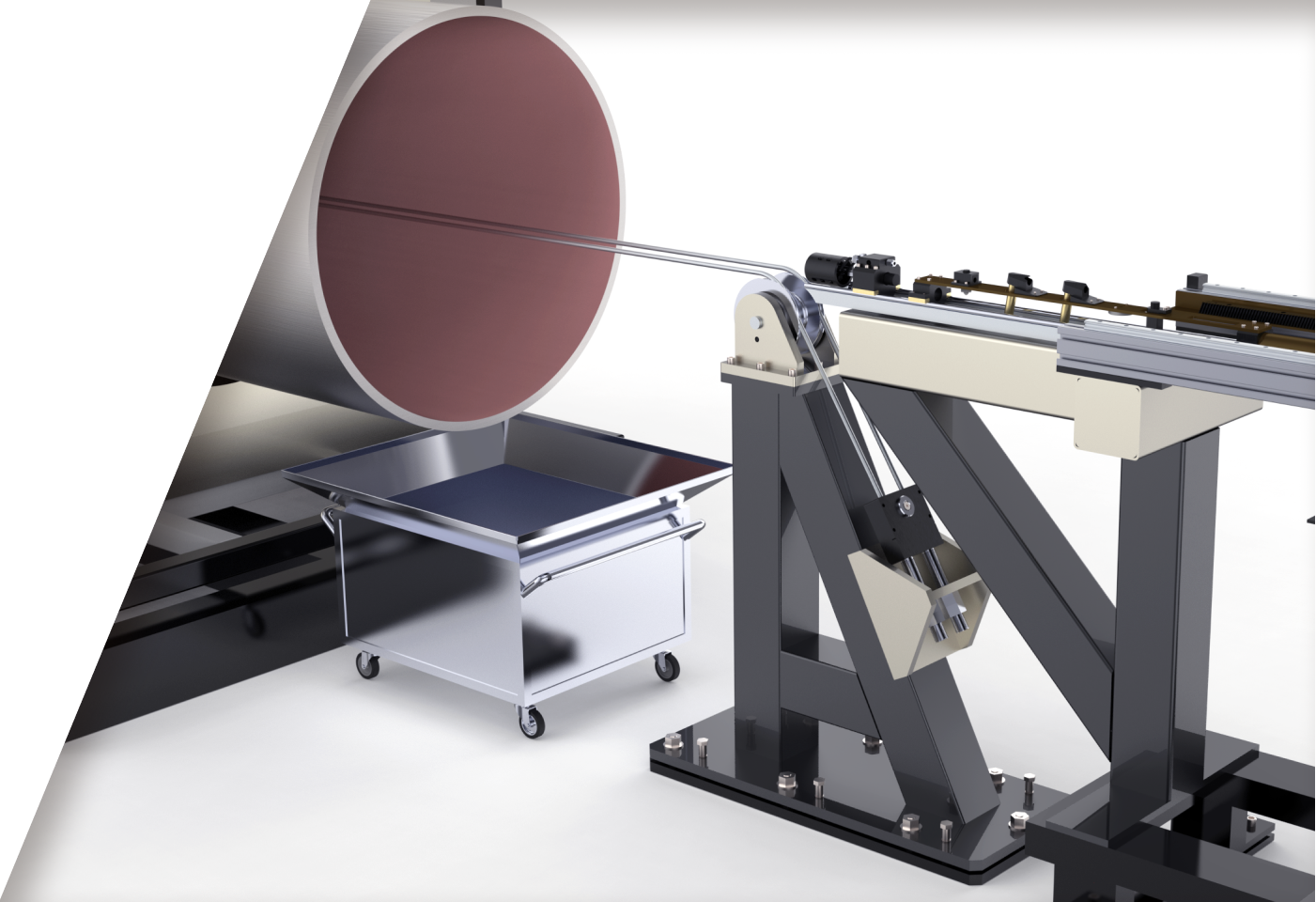

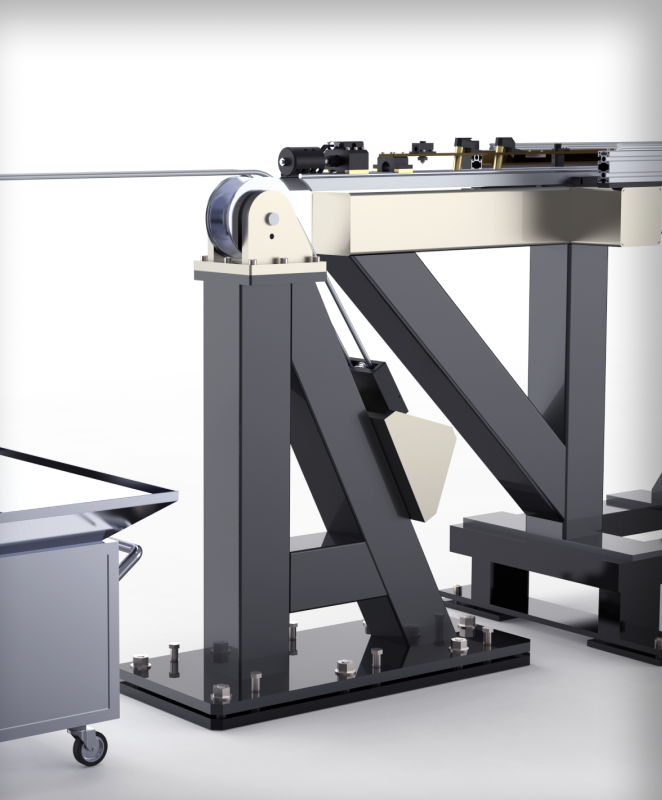

The various spraying jets for air, water, dye & developer are mounted on a torch lance that is moving in sync with rotation along the linear axis.

The parameters like surface speed, step over, etc will be programmable and controllable via plc and will have overrides through a handheld wireless remote pendant. test

6 to 36 pipe as standard

1.5 to 12 mtr pipes in length

Waste recovery bins at either ends

15 HMI touch screen along with wireless pendant.

HD camera with 24 led monitor for visual inspection.

High-end VFD operated pumps for water, dye & developer ensuring precise quantity of respective fluids.

Precision jets for controlled spraying of water, air, dye & developer

Standalone module of ss tubing for process fluids

VFD operated pumps for accurate flow rates.

Precise position tracking of weld defect using camera in tandem with software